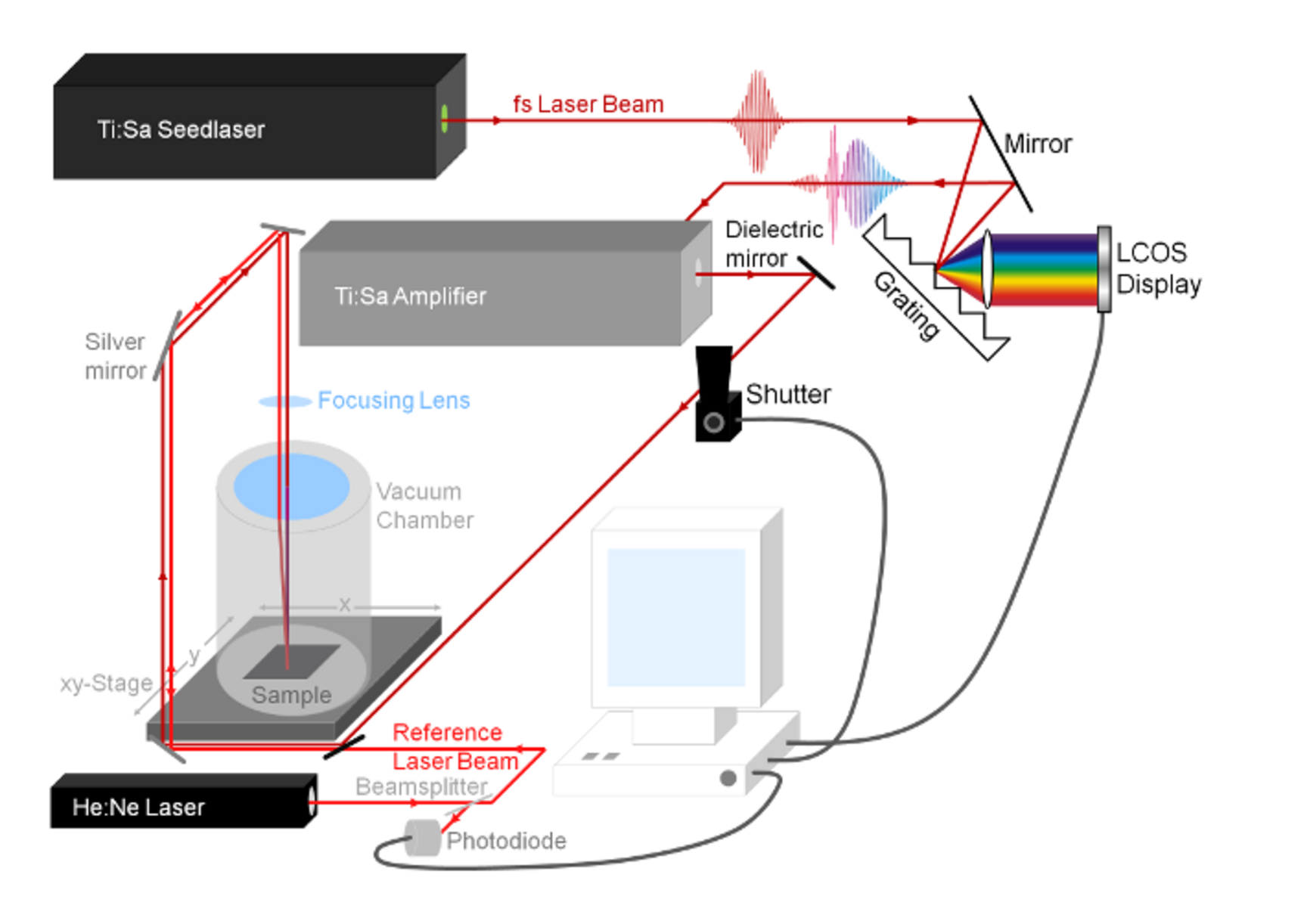

Photonic processes, in particular laser based material processing methods allow for a variety of possibilities to provide materials with novel characteristics. Especially laser beam sources, emitting ultrashort laser pulses in the femtosecond regime (10-15 s), enable the realization of novel material properties. On this time scale, light – material interaction is too short for an efficient heat transfer into the material. Consequently, the processed material does not melt but micro- or nanostructures build up within the area of the laser focus. Depending on the laser pulse parameters (pulse energy, pulse duration, number of pulses, shape of pulse, wavelength of the laser) a variety of structures can be adjusted. Moreover, tailored laser pulses can be formed individually by adaptive dispersive optical elements. A feedback loop can be implemented for monitoring the emerging structure of the surface during laser processing. This enables a setup of a closed process loop with a self-learning algorithm which is used to optimize the shape of femtosecond laser pulses (figure 1).

Another aspect is femtosecond laser structuring processed under reactive gas atmospheres such as oxygen or elemental halogens which can assist in the structuring process and provide further surface properties.

For surface processing, different process stands are available for samples with dimensions < 100 µm to >1 m with various laser sources from nanosecond to femtosecond pulses with an optical output power ranging from 10 µW to 400 W. Contact us for attractive offers for targeted surface modification of almost any solid material.

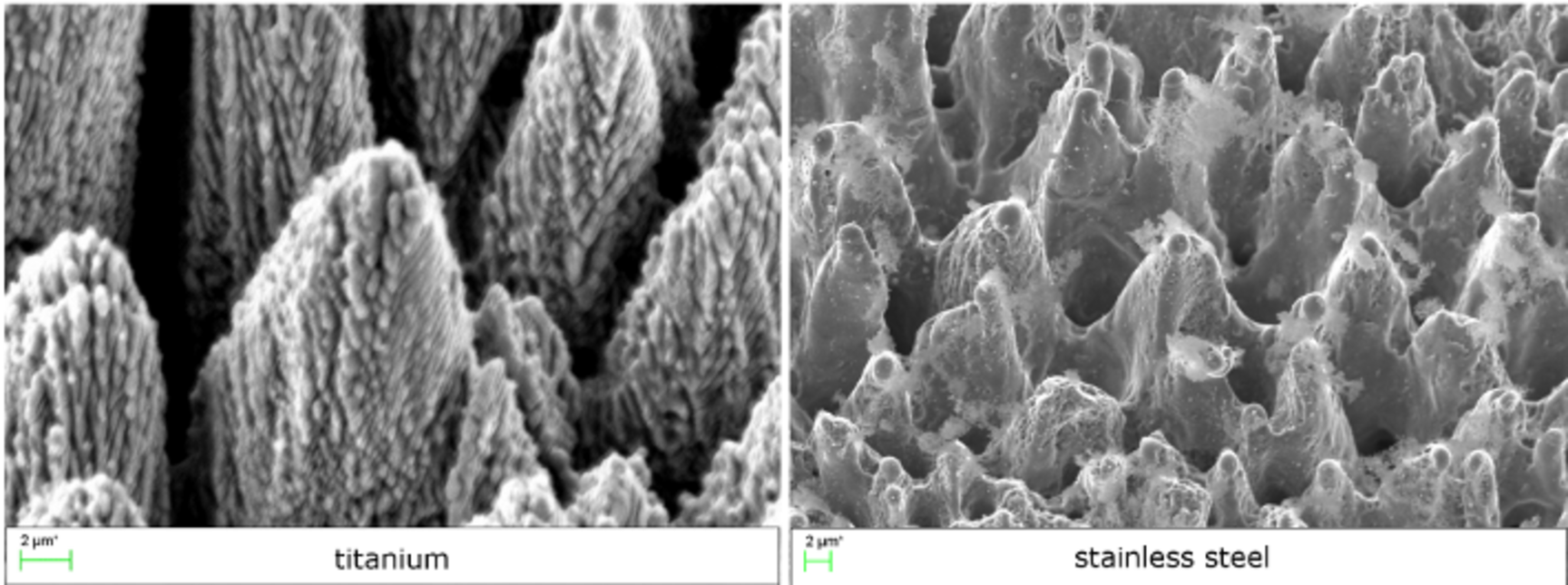

Examples of materials with tailored surface properties include:

Hydrophobicity/Superhydrophilicity: Hydrophobic surfaces can be achieved by appropriate nano- and microstructures and they provide dirt-repellent properties (figure 2). On the other hand, superhydrophilicity for improved wetting characteristics can be achieved.

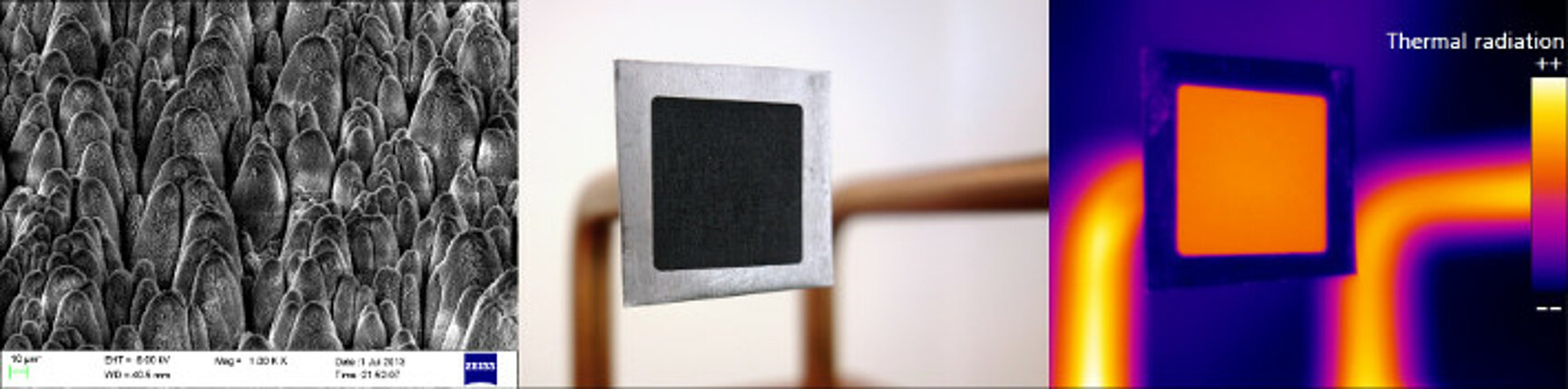

Heat sink: The characteristic surface appearance of micro structured metal surfaces is a spiked-structure at the micrometer level (figure 3). Aluminum plates with micro structured surfaces provide significantly enhanced heat radiation and can be used for radiative cooling (figure 4). In comparison to conventional heat sinks the weight and volume of the micro structured aluminum plates are strongly reduced.

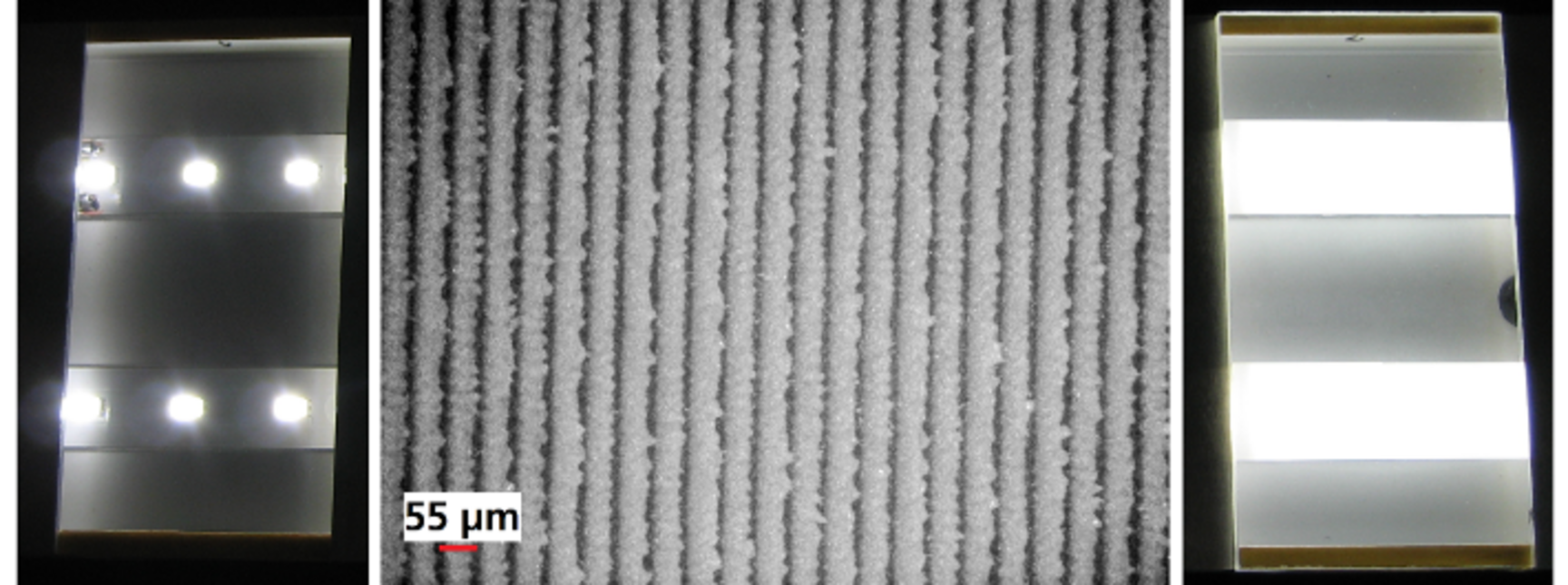

Optics: The reflectivity of the laser structured surfaces can be adjusted precisely with the choice of tailored laser pulses. This can be used to fabricate non-reflective metal surfaces (black metals), reflection standards for optics or diffuse scattering screens for lightning applications with LEDs (figure 5).

Photovoltaic: Femtosecond laser structuring of silicon in SF6 atmosphere shifts light absorption towards the mid infrared which makes such materials attractive for solar industry or as elements for NIR detectors.

Energy storage: Nanostructured surfaces of electrodes are promising candidates for enhanced production of hydrogen (see project GreenH2) or for novel rechargeable zinc-air batteries (see project ZiLsicher).

Catalysts: Surface structuring of heterogeneous catalysts can significantly improve the catalytic activity and allow for the production of compact and mobile reactors for dehydrogenation (see project LOHC).