August 18, 2016

SMARTTUBE – Smart pipe system

Co-funded by the Federal Ministry for Economic Affairs and Energy (BMWi),

AiF-ZIM

Duration: December 2014 – November 2016

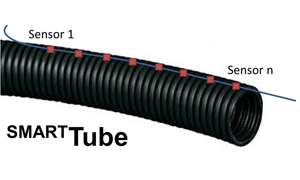

The idea consists in the realization of a smart pipe system (SMARTTUBE) in which fiber optic sensors allow chemical analyses and the measurement of physical parameters, such as the distributed temperature, pressure, and the three-dimensional shape determination of the overall system. The possibility of real-time monitoring of fluids in, for example, industrial processes as well as the monitoring of the actual line systems (condition monitoring) with one and the same fiber optic sensor offers users total system monitoring of critical components.

The SMARTTUBE-system should easily be integrated in a smart factory, where high sensor density and automation technology process for self-tuning, self-configuring and self-diagnosis is realized (industry 4.0).

The aim of this project is the development of an intelligent pipe system (SMARTTUBE) for monitoring following parameters:

- specific molecule concentrations,

- distributed temperature measurement,

- pressure measurement, and the

- three-dimensional shape determination of the system

This should be made possible with a single fiber-optic sensor, to maintain the integration and installation costs as low as possible.

The common physical basic concept is called Fiber Bragg Grating (FBG), a microscopic periodic refractive index modulation within the core of an optical fiber. Through the use of femtosecond laser technology, it is now possible to process these periodic refractive index changes directly with the highest degree of flexibility not only in the core of a fiber, but also in the cladding of the fiber. Due to this new technology and the possibility of processing various sensor types with different functionalities at once, completely new approaches can be provided to the customers.