Duration: September 2019 - August 2021

Co-funded by

Bundesministerium für Wirtschaft und Infrastruktur (BMWI), Fördermaßnahme Zentrales Innovationsprogramm Mittelstand (ZIM)

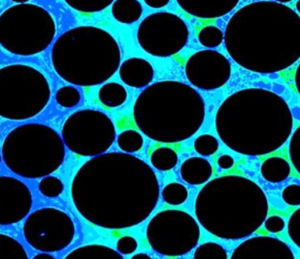

Microfluidic models for the simulation of rocks of a certain porosity and permeability under laboratory conditions provide important information for the petroleum industry, where e.g. the ability of chemicals to supersede oil out of the pores is investigated.

For this application, stochastic or deterministic structures, consisting of “grains” and “pores”, have to be developed, produced, and validated. The flow processes that occur when a second fluid is injected can be examined in detail on the system that was previously filled with oil. The micro-models currently used for such investigations consist of structured silicon, provided with glass lids that serve as models for the porosity of the rock. The oil displacement process is recorded with a camera and analyzed using image recognition algorithms. This allows the oil displacement speed and the effectiveness of the displacement process to be determined very well. However, a purely photographic evaluation of the fluid flows can be imprecise or even flawed. No physical parameters such as temperature, pressure, or mixing ratio of the process fluids can be determined through the photographic analysis. However, these parameters are of great importance for the fundamental understanding of the displacement process and the knowledge of only one of the named quantities considerably increases the parameter space for the optimization of oil displacement processes.

Within the framework of the project, the partners aim to develop and produce microfluidic systems that consist of stochastically or deterministically of “grains” and “pores” structures. The flow processes that occur when a second fluid is injected can be examined in detail on the system that was previously filled with oil. In addition, the microfluidic systems are to be improved in terms of measurement technology using optical sensors so that, for example, a two-phase flow can be precisely determined locally in the fluid by determining the refractive index or the system temperature.